Desander Cyclones

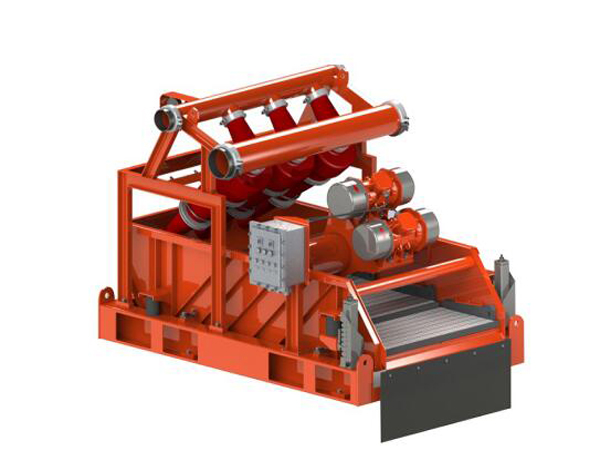

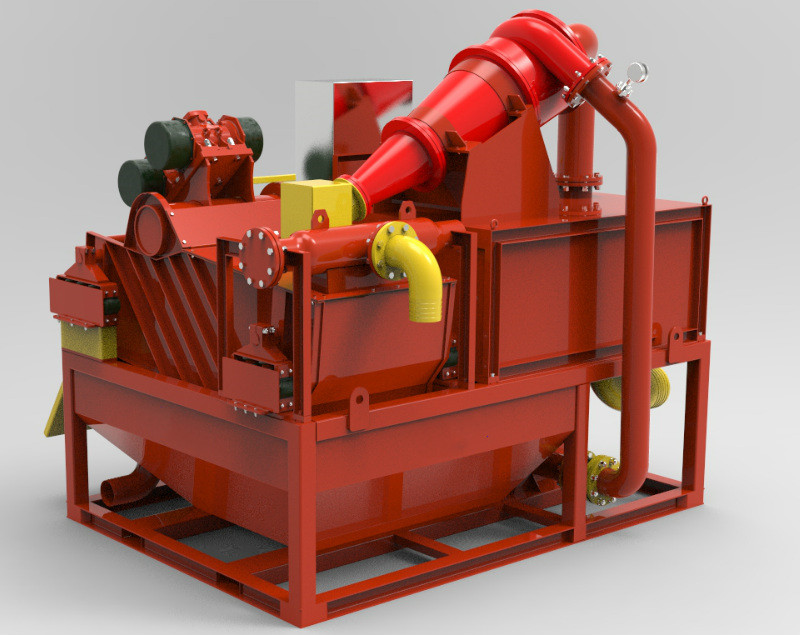

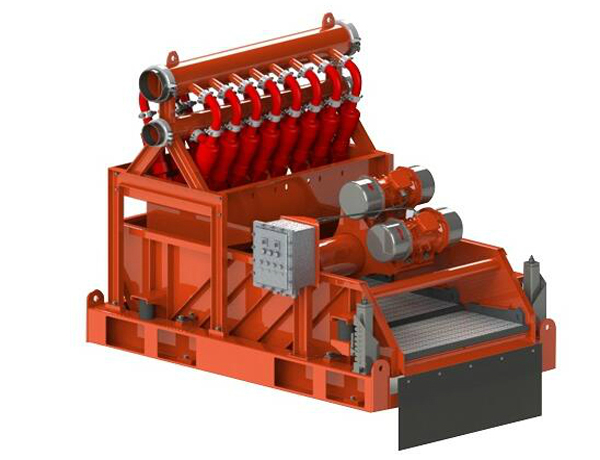

Our specially engineered hydro-cyclone units are highly effective in removing sand and silt from drilling fluids. Constructed with abrasion-resistant polyurethane, these units can be used individually or assembled above shale shakers. You have the flexibility to customize the number of cones to,

Product Features

KES Separation Desander Cyclones- Efficient Sand & Silt Removal for Drilling Fluids

Optimize your drilling fluid cleaning with KES Separation’s high-performance Desander Cyclones. These specially engineered hydro-cyclone units are constructed from abrasion-resistant polyurethane, ensuring durability and longevity in demanding environments.

Designed for efficient removal of sand-size and silt-size particles (40-100 microns) from returned drilling fluids, our desander cyclones are a crucial component for effective solids control.

Customizable Desander Cyclones- 500 GPM Performance for Drilling & Construction

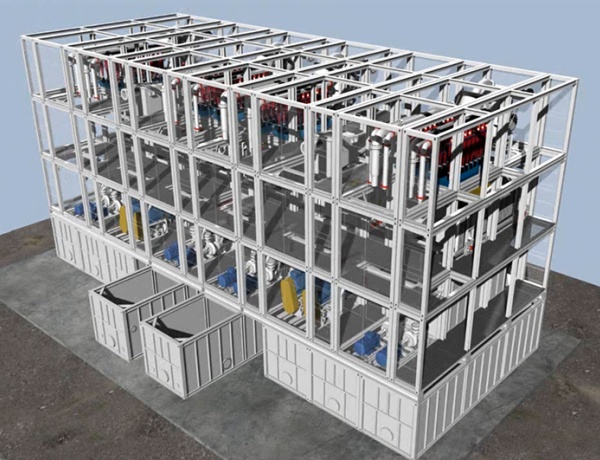

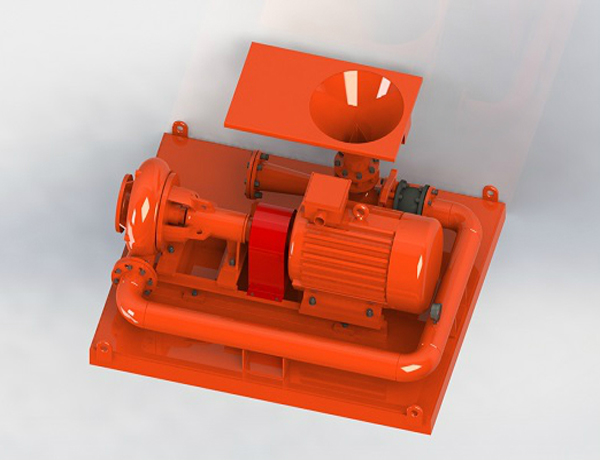

Whether used individually or assembled above shale shakers, our desander cyclones offer flexible and customizable solutions with a compact design and small footprint.

Each 10″ hydrocyclone can process 500 GPM at 75 feet of head, making them ideal for oil & gas drilling, foundation construction, mining, municipal sludge, HDD, CBM, and TBM mud systems.

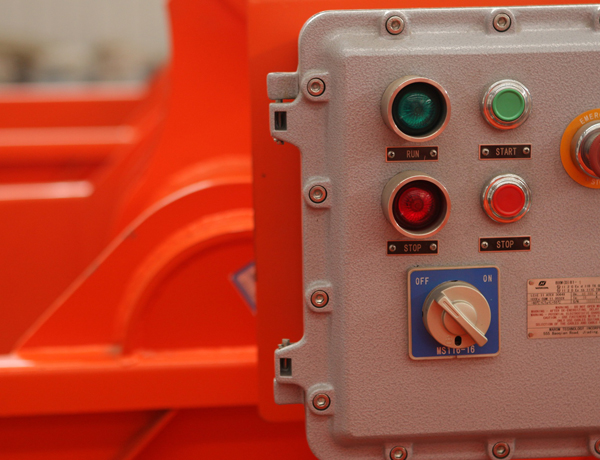

Key Benefits:

- Highly effective in removing fine particles (sand and silt).

- Durable, abrasion-resistant polyurethane construction.

- Flexible deployment options (stand-alone or integrated).

- Customizable to suit specific operational needs.

- Contributes to cleaner drilling fluids and improved system performance.

FAQ:

Q1: What are Desander Cyclones used for?

A1: Desander cyclones are primarily used to remove sand-size and silt-size particles (typically 40-100 microns) from drilling fluids, ensuring cleaner mud and more efficient drilling operations.

Q2: What material are KES Separation Desander Cyclones made from?

A2: Our desander cyclones are constructed with high-quality, abrasion-resistant polyurethane for maximum durability and a long service life.

Q3: Can these desander cyclones be integrated into existing systems?

A3: Yes, KES Separation Desander Cyclones can be used individually or easily assembled above shale shakers, offering flexible integration into various mud systems.

Q4: What is the processing capacity of each Desander Cyclone cone?

A4: Each 10-inch drilling mud desander hydrocyclone cone is capable of processing 500 gallons per minute (GPM) at 75 feet of head.

Q5: What industries can benefit from using Desander Cyclones?

A5: Desander cyclones are widely used in oil & gas drilling, foundation construction, mining sludge, municipal sludge, HDD mud systems, CBM mud systems, and TBM desanding plants.

Parameters and configurations:

| Model | Capacity (m3/h) | Desander Cone Size (in) | Number of Desander (ea) | Working Pressure (Mpa) | Feeding/Output (in) |

| 1S | 120 | 10 | 1 | 0.25-0.4 | 6 / 8 |

| 2S | 240 | 10 | 2 | 0.25-0.4 | 6 / 8 |

| 3S | 360 | 10 | 3 | 0.25-0.4 | 6 / 8 |

| Model | Capacity (m3/h) | Desander Cone Size (in) | Number of Desander (ea) | Desilter Cone Size (in) | Number of Desilter (ea) | Working Pressure (Mpa) | Feeding/Output (in) |

| 1S8N | 120 | 10 | 1 | 4 | 8 | 0.25-0.4 | 6 / 8 |

| 2S12N | 240 | 10 | 2 | 4 | 12 | 0.25-0.4 | 6 / 8 |

| 3S16N | 360 | 10 | 3 | 4 | 16 | 0.25-0.4 | 6 / 8 |

Contact Us Today to discuss your specific requirements. You can also reach us directly via WhatsApp at +86-15603054293 or email at [email protected].