Desilter Cyclones

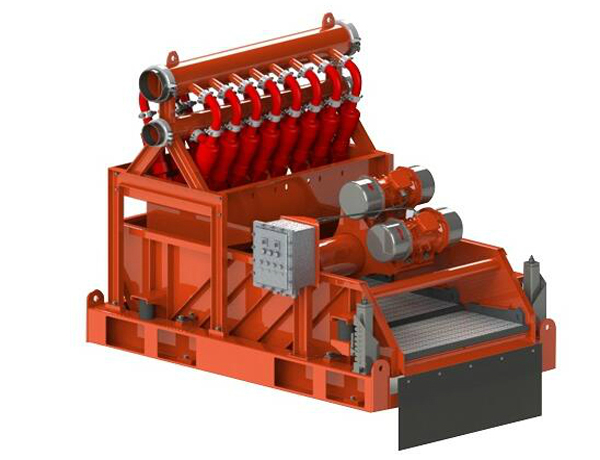

Our specially engineered hydro-cyclone units efficiently remove sand and silt from drilling fluids. Made with abrasion-resistant polyurethane, they can be used individually or assembled above shale shakers. Customize the number of cones to meet your specific needs and improve your drilling operation

Product Features

The best Desilter Cyclones – Advanced Solid Control for Drilling Operations

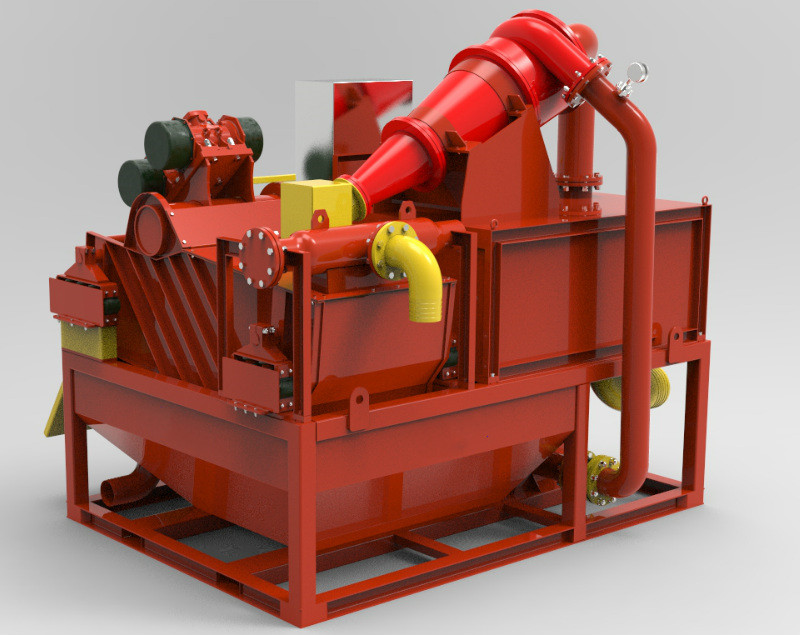

The Desilter Cyclones from KES Separation are purpose-built hydro-cyclone units designed to effectively remove silt-sized solids (12 to 74 microns) from drilling mud. Made from durable, abrasion-resistant polyurethane, these units are essential for maintaining the integrity and efficiency of your drilling fluids. By removing harmful solids, our desilters help prevent equipment wear, reduce maintenance costs, and improve overall drilling performance.

Key Features and Benefits for Desilter Cyclone:

- Customizable and Flexible Design: The number of cones can be tailored to meet your specific capacity needs, with models ranging from 8 to 16 cones. The compact design and small footprint allow for easy integration into existing drilling mud systems.

- High-Quality, Durable Construction: The 100% polyurethane hydrocyclone construction ensures long-lasting performance and high resistance to the abrasive nature of drilling mud.

- Optimized for Silt Removal: Each cone is a 4-inch desilter hydrocyclone, engineered for maximum efficiency in separating fine solids.

- Variable Apex Inserts: These units feature variable-size apex inserts, offering flexibility to accommodate different drilling conditions and fluid properties.

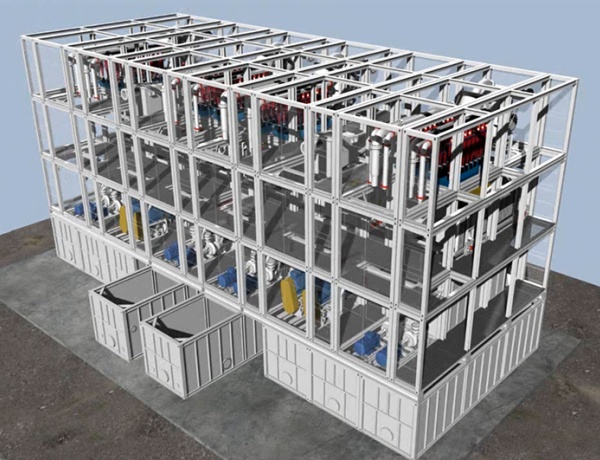

High-Performance Solid Control Equipment for Oil & Gas Drilling

Our desilter cyclones can be used as stand-alone units or mounted above shale shakers, offering a versatile solution for any solids control system. They are a critical component for any drilling mud system, especially in the oil and gas industry.

FAQ:

Q1: What is the main purpose of a desilter cyclone?

A1: A desilter cyclone is used to remove fine solids, specifically silt and fine sand ranging from 12 to 74 microns, from drilling fluids to improve the mud’s properties and protect downstream equipment.

Q2: How do desilter cyclones work?

A2: They operate using centrifugal force. Drilling mud is pumped into the cone at a high velocity, creating a vortex. Heavier solid particles are forced to the outer wall and discharged from the bottom (apex), while the cleaner fluid spirals upward and exits through the top.

Q3: Can these desilter units be customized?

A3: Yes, our desilter cyclones can be customized in terms of the number of cones to match your specific solids control requirements and desired capacity.

Q4: What materials are the cyclones made from?

A4: The hydrocyclones are constructed from 100% abrasion-resistant polyurethane, ensuring durability and a long service life in harsh drilling environments.

Hydrocyclone Unit Configurations:

| Model | Capacity (m3/h) | Desilter Cone Size (in) | Number of Desilter (ea) | Working Pressure (Mpa) | Feeding/Output (in) |

| 8N | 120 | 4 | 8 | 0.25-0.4 | 6 / 8 |

| 12N | 240 | 4 | 12 | 0.25-0.4 | 6 / 8 |

| 16N | 360 | 4 | 16 | 0.25-0.4 | 6 / 8 |

| Model | Capacity (m3/h) | Desander Cone Size (in) | Number of Desander (ea) | Desilter Cone Size (in) | Number of Desilter (ea) | Working Pressure (Mpa) | Feeding/Output (in) |

| 1S8N | 120 | 10 | 1 | 4 | 8 | 0.25-0.4 | 6 / 8 |

| 2S12N | 240 | 10 | 2 | 4 | 12 | 0.25-0.4 | 6 / 8 |

| 3S16N | 360 | 10 | 3 | 4 | 16 | 0.25-0.4 | 6 / 8 |

Ready to Optimize Your Drilling Operations? Contact us today to find the perfect Desilter Cyclone solution for your solid control needs. Our experts are here to help you select the ideal model to boost your drilling efficiency and lower operational costs.