Drilling Cuttings System

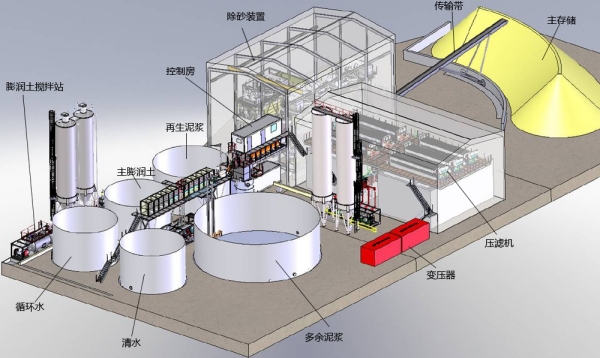

The KES Separation drilling cuttings system separates and recycles oil-based mud from drill cuttings, reducing the volume of cuttings and thermal operation costs. It can reduce OOC to 3-5% for OBM cuttings and recycle drilling fluids for reuse.

Product Features

The KES Separation drilling cuttings system separates and recycles oil-based mud from drill cuttings, reducing the volume of cuttings and thermal operation costs. It can reduce OOC to 3-5% for OBM cuttings and recycle drilling fluids for reuse.

Product Features

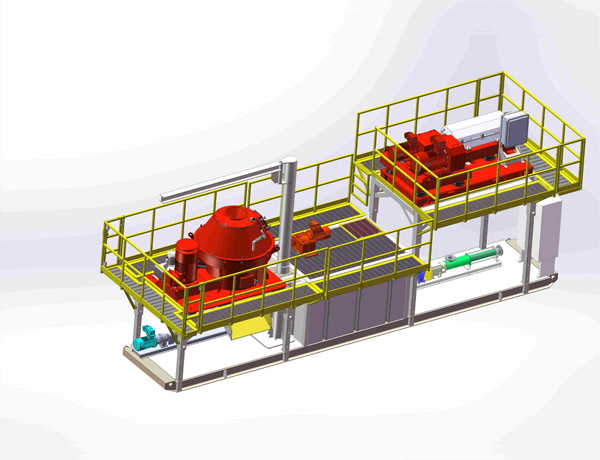

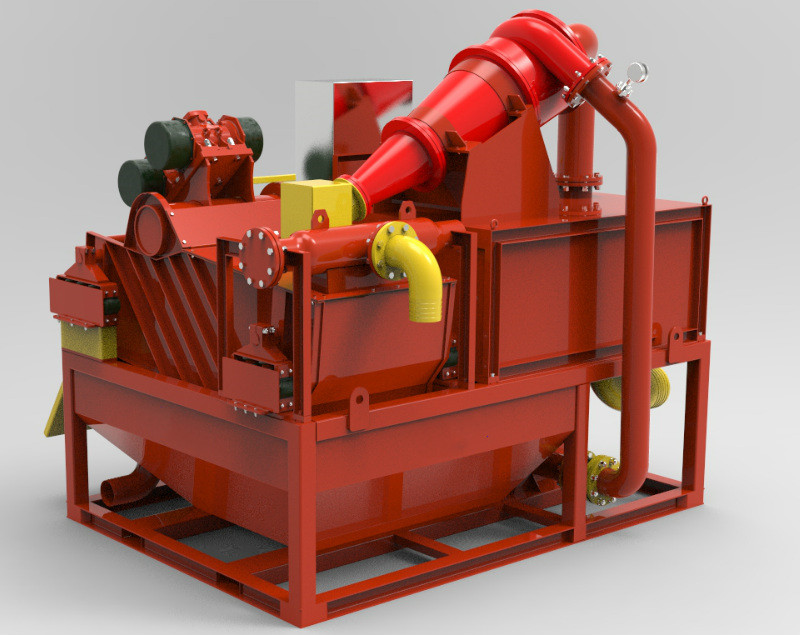

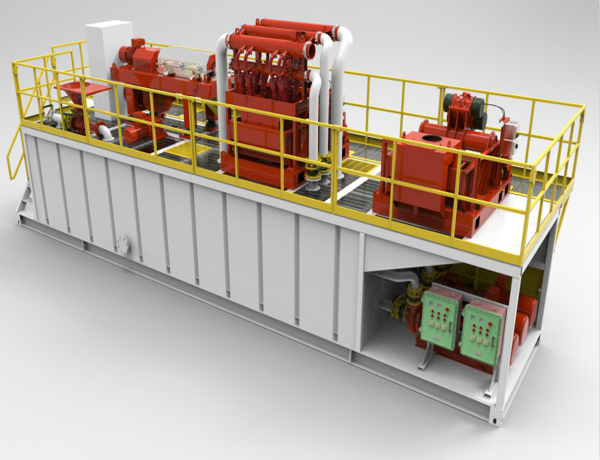

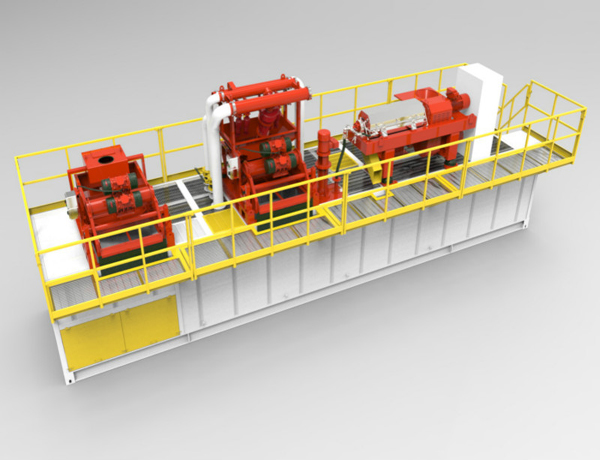

KES Separation drilling cuttings system is mainly composed of screw conveyor, vertical cutting dryer, telescopic skid with mud recovery tank and agitator, mud transfer pump, cuttings collection skip etc. KES Separation drilling cuttings clean system is used to separate and recycle the oil-based mud adhering to the drill cuttings, and minimize the volume of drill cuttings in order to save cost of thermal unit operation.

- For OBM cuttings, the system can reduce the OOC- oil on cuttings to 3~5%;

- For WBM cuttings, we don’t recommend to use vertical cuttings dryer;

- The drill cuttings system can recycle the drilling fluids for reuse to save drilling cost;

- The drill cuttings system can reduce the volume of final cuttings tosave cost of thermal operation;

- The drill cuttings system cansave cost of thermal operation.

KES Separation Drilling Cuttings Treatment System Components:

| S/N | Product | Description |

| 1 | Vertical Cuttings Dryer | KSCD-930 with fixed speed control panel or VFD control panel |

| 2 | Screw Conveyor | Used to collect the drill cuttings discharged from shaker, and transfer to feed to vertical dryer |

| 3 | Telescopic Skid with Transfer Pump | The skid is used to support the vertical dryer, to collect the recycled OBM discharged from vertical dryer, transfer pump installed on the skid will transfer the OBM back to active solids control system |

| 3 | Mud Skips | Can be used to collect the cuttings discharged from vertical dryer |