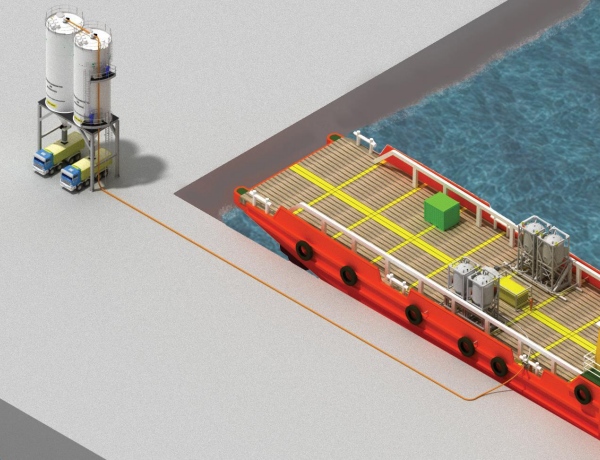

Oil Drilling Mud System

Oil drilling mud systems use multiple tanks to circulate mud, including a shaker tank, centrifuge tank, mixing tank, reserve tank, and trip tank. KES Separation offers various sizes of mud systems up to 3000HP, with different capacities.

Description

Oil Drilling Mud System is a multi-tank mud system including shaker tank, centrifuge tank, mixing tank, reserve tank or mud storage tank and trip tank. By connecting with rig and mud pump, it forms closed loop mud circulation system. The mud system also called solids control system, or mud circulation system for the oil gas drilling operations. KES Separation oil drilling mud system is available for different oil drilling rig sizes from 250HP to 3000 HP with different capacity.

The solids control equipment involved in mud system as follows:

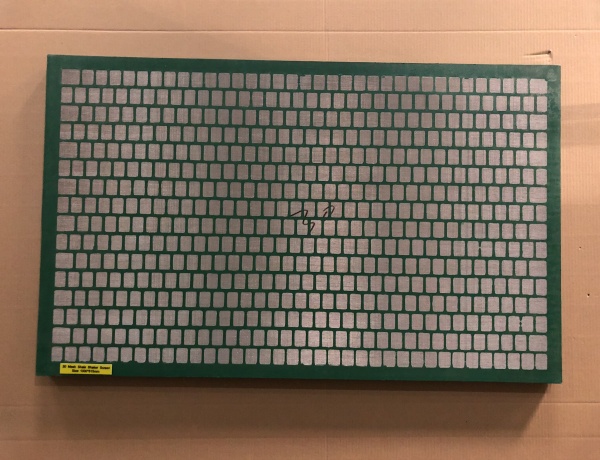

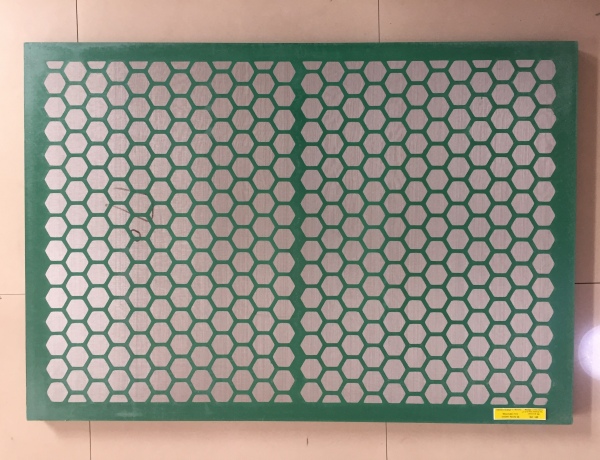

- Shale Shaker for first phase solids control, to remove 100 microns solid particles;

- Desander cyclones for second phase solids control, to remove cuttings 40 microns solid particles;

- Desilter cyclones for third phase solids control, to remove cuttings 20 microns solid particles;

- Decanter Centrifuge for last phase solids control, to remove 2-7 microns fine solids, we call it mud weight cutting process.

Oil drilling Mud System normally including following mud tanks depends on the configuration:

- Shaker Tank (It normally equipped with 2 or 3 units shaker, desander, desilter);

- Centrifuge Tank (It normally equipped with 2 or 3 units high speed and low speed decanter centrifuge);

- Mixing Tank (It normally equipped with several sets mud agitators, mud hoppers and jet mud mixers);

- Storage Tank (It normally equipped with mud agitators, and connect to mud pump).

Reviews

There are no reviews yet.