Oil drilling mud system has the upmost demand for the shale shaker treatment, it normally required heavy duty and large capacity shaker with 4-panel or 3-panel shaker screens. With over 10 years working experience in the design and manufacturing of shale shakers & centrifuges, we can design different model shaker, elliptical motion track shaker or linear motion track shaker to fit for the technical requirement of customers.

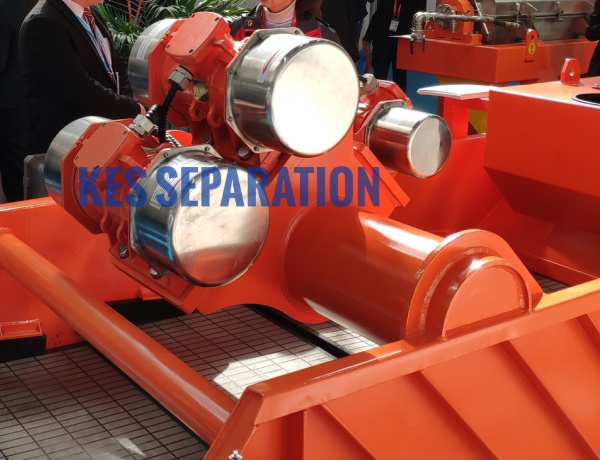

Elliptical vibrating shaker adopts two un-balanced vibrating motor, one big motor and one small motor with different mass and diameter to achieve the elliptical movement of the shaker deck in a certain direction. The elliptical movement shaker screen has large capacity and faster separation performance compared with Linear vibrating shaker.

Linear vibrating shaker adopts two vibrating motors with same size, same G-Force to achieve the linear movement of the shaker screens. The linear motion vibrating screen is very common and easy to design and easy for operation. Compared with Linear motion vibrating screen, the elliptical vibrating screen is normally applied in some special work condition.

Dual Track vibrating shaker is the

combination of linear vibrating shaker and elliptical vibrating shaker.

According to the work condition requirement, the user can switch the vibrating

mode by the switch on the control cabinet. There are 3 vibrating motors

installed on the beam of the shale shaker. When operate in linear motion

shaker, the 2 big motors will work synchronously and the small vibrating motor

stop work. When operate in elliptical motion shaker, one of the big motors and

the small motor will work together and the other big motor don’t work.

It is not easy to design a well-built heavy duty dual track vibrating shaker; it requires many years’ experiences in solids control & drilling waste management. The engineers should know the mud condition of oil drilling rig. Our chief engineer started to work in this field since 2008, and after so many years, we have accumulated vast knowledge in the equipment for oil drilling mud treatment. Based on that, we are keeping upgrade the design of the shale shakers, centrifuges, screw conveyors and other solids control equipment. Meanwhile, we are also keep upgrading the material selection and manufacturing process to make a guaranteed product.

Dual connection shaker or Triple connection shaker is also very popular for oil drilling companies. Some drilling contractor will produce the mud tanks locally to save sea freight transportation cost and will source the shale shakers from China. After the drilling contractor provide the installation size to China solids control equipment manufacturers, we can recommend suitable shale shakers in dual or triple connection. When the drilling contractor receive the dual connection vibrating shakers or Triple connection vibrating shakers, they can easily install the shale shaker to the mud tank and start to use conveniently.

Except for dual connection shale shaker, dual centrifuge system is also very popular in rig site application. One centrifuge might work in middle speed to recovery barite; the other one centrifuge work in high speed to cut mud weight. In many oil drilling sites, it is not necessary to recover barite and the solids control service company will provide dual sets high speed centrifuge work together to cut mud weight. If you have any requirements, please contact us freely. Email: sales@kesseparation.com